Evince Group is amongst those few Bangladeshi textile and apparel giants that are truly vertical integrated companies. It has a 100 per cent yarn-dyed woven fabric facility, a green factory for apparel production and a strong retail presence with brands like Miniso Bangladesh and Noir. Interestingly all the divisions of the group are on growth track. The youngest member of the group’s board and business graduate from Pace University, New York, Shah Rayeed Chowdhury has been involved in this business for more than a decade now. Passionate about sustainability, Rayeed acts as a driving force for the company and is helping the organisation take greater strides.

Strong raw material base

“State-of-the-art infrastructure backed by expansion at the right time is the backbone of the group,” shares Rayeed. The group has periodically invested in fabric as well as garment production. In raw material production, the group’s thrust is on cotton base as it offers 100 per cent cotton yarn dyed shirting fabrics comprising a variety of yarn counts with a wide range of dobby designs and different types of weaves with enormous colour combinations.

The group’s focus is on denim and other suppliers for top retailers like H&M, Zara, Kiabi and many European renowned brands and retailers.

“We have established Argon Denims with a wide range of weaving, colour combination, quoting, different finishes and mercerisation using about 160 state-of-the-art high-speed and dobby Picanol looms from Belgium, finishing machines from Italy, warping and dyeing from Taiwan, mercerising machines from India,” says Rayeed.

Sustainable raw material and energy conservation

“We value sustainable practices as part of our responsibility,” says Rayeed. The company uses a wide variety of raw materials like recycled yarns, organic cotton certified by Organic Cotton Accelerator (OCA), BCI, The Primark Sustainable Cotton Programme (PSCP), Post-Consumer Waste (PCW), Cotton made in Africa (CmiA), etc.

The group’s facility is running on its own power generation of about 4.5 MW from natural gas and proceeding for renewable solar power too. It saves at least 34 per cent more water than the conventional process by its self-made, eco-rich process.

“We are in the process of establishing a modern washing lab centre and using processes/machines like e-Designer, Environmental Impact Measurement (EIM) system, Ozone Treatment, Jeanologia G2, Jeanologia Mambo 18 & 60, etc., which help in multiple usage of denim fabric,” shares Rayeed as part of their future plans.

| The facility is fully equipped with an efficient lab for shade matching and colour development. Vessel capacities range from 5 kg to 500 kg, supported by three 400 kg pressure dryers while all looms are capable of 8 colours in the weft and equipped with Electronic Dobby. Furthermore, several looms are equipped with double beams to handle seersuckers and designs with varying warp tension. In addition to that, there are 40 latest Airjet looms from Toyota Japan which can run up to 850 RPM. |

Garmenting is the focus

Evitex Dress Shirt Ltd. (Gazipur), consists of 30 lines producing 6.5 to 7 lakh pieces of shirts per month and Evince Garments and Evitex Apparels have 15 lines and 26 lines respectively, producing men’s shirts and women’s tops.

“Going forward, we are expanding into garmenting and we will come up with a new factory that can produce diverse products such as denim, activewear as we are witnessing good demand for these products,” affirms Rayeed.

As a part of its business strategy, the group has a big mix of buyers to ensure proper capacity utilisation as it is catering to online stores like ASOS, Myntra, Boohoo, high-street brands like Zara, Next and stores like Tesco, Carrefour and many more in various segments. Overall Evince Group is working with close to 30 buyers but hunting for new clients is a regular process for it.

Rayeed opines, “We have learned from the past that depending on a few big buyers only is not the right strategy and it can leave empty capacity at any time. We are also not limited to a particular country or region, so apart from core traditional markets, there is hardly any country in emerging or non-traditional markets which is not on our radar.”

Thrust on R&D, technology and product development

“For us, investing in new technology is a regular practice and we will continue doing the same. We invest a lot of time exploring new technology as such kind of learning is never-ending and provides major solutions for the cost aspect,” says Rayeed and further adds that there is more thrust required to guide the exporters about the latest machines and technology available and their proper use.

| Details of production capacity and infrastructure |

| 8,000 kg per day yarn dyeing capacity |

| 30 million yards of denim fabric per year |

| 156 Italian rapier-weaving machines |

| 71+ garment lines |

| 1.5 million pieces of garments per month |

Green factory with thrust on worker welfare

Evitex Dress Shirt Ltd. (Gazipur) is a beautiful two-storey factory of the group which is also LEED Platinum certified (US Green Building Council) with ample open space (40 per cent) and ensures maximum use of sunlight, airflow at every nook and corner of the factory. The factory’ aesthetic is also pleasing.

However, the major focus is on worker welfare as there are sufficient arrangements for emergency healthcare of the workers when needed besides a medical centre which has been set up so that healthcare services can be provided during factory operations. Numerous doctors and trained nurses provide their assistance in the centre and regular health check-up camps for eyes and breast cancer have helped a large number of workers of the group.

“Sustainability is our approach and we put in continuous efforts to improve processes and control use of water, electricity and materials,” avers Rayeed. Measuring the use of natural resources to ensure transparency with buyers and imbibing sustainability as part of the DNA is what makes Evince Group a differentiator.

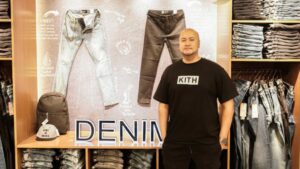

Growing retail footprint

With Miniso (master franchisee of a globally renowned Japanese designer brand) and Noir (an in-house premium brand), the group has a strong focus on the retail sector.

Currently, it has 30 stores under the franchise model and offers 12 product categories of textile and lifestyle products and is not only limited to Dhaka but spread across Bangladesh. Rayeed believes that Bangladesh will be renowned for retail shortly and the group will ensure its good share in this segment also.