The global apparel and footwear industry is both dynamic and complex, with supply chain challenges that can significantly impact the bottom line of the business. Manufacturing is one of the impacted areas where factors like inventory management, process visibility, quality and productivity issues, lead times amongst others play a pivotal role in shaping the future.

Many players in the fashion industry have come to realise that embracing digital transformation is a necessity for survival. The need to digitise processes is not only a strategy for risk mitigation but also a means to ensure agility, sustainability and profitability in businesses. A compelling aspect driving this shift is the trend of fashion brands favouring technologically advanced suppliers, as a reliable and efficient supply chain is the key consideration for any brand.

Despite the universal importance of digital transformation, fashion manufacturers, apparel and footwear factories in particular, find themselves at various stages of this evolutionary journey. Some, however, have been hesitant to embrace the call for digital transformation, which is further fuelled by uncertainty and an understandable confusion about where to commence the digital journey!

The dilemma lies in determining whether to invest in 3D design, procurement and costing tools, workforce management solutions, logistics technologies, fabric optimisation tools, advanced analytics or artificial intelligence. The complexity of this decision-making process adds to the challenges faced by manufacturers.

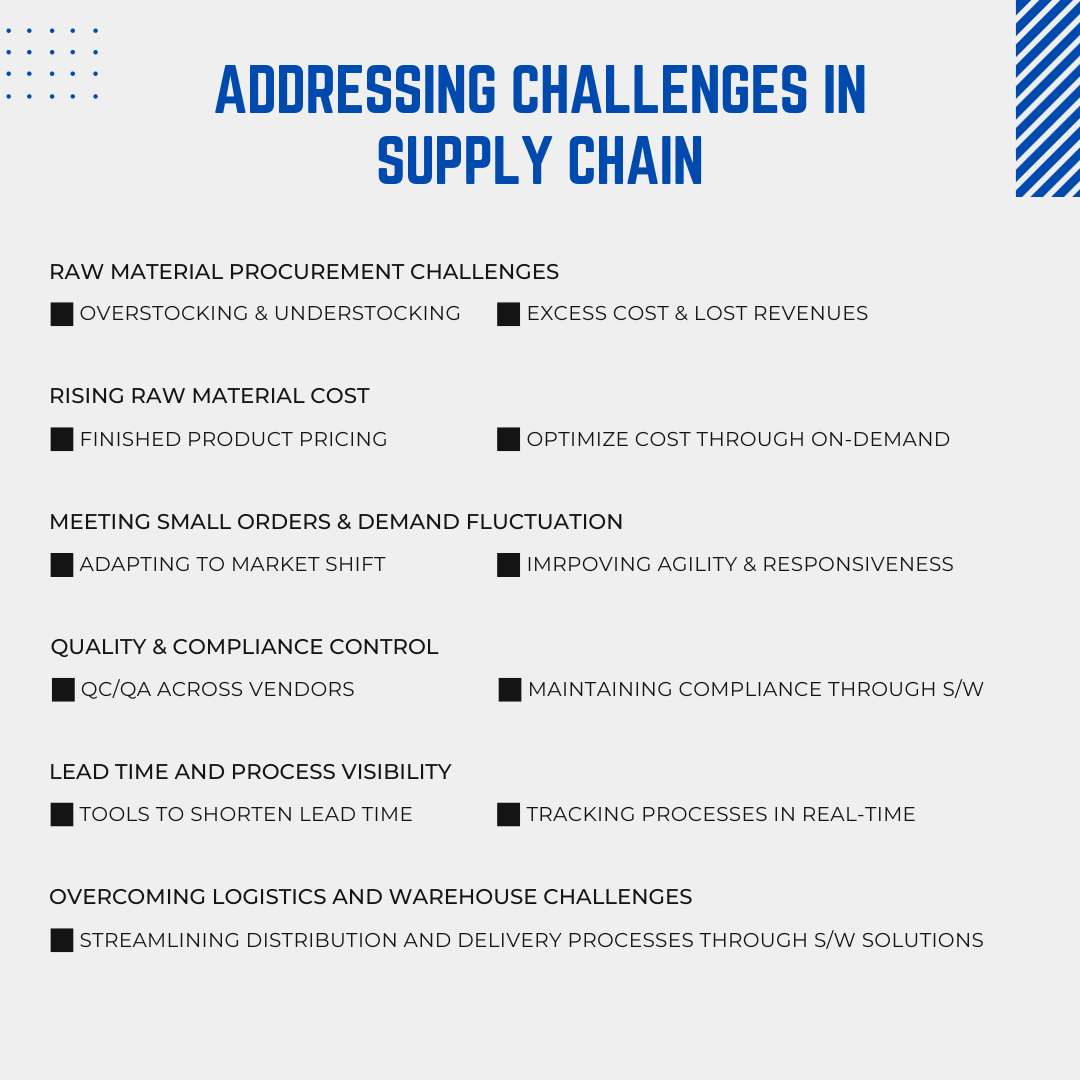

While there’s no universal, definitive technology solution that will have the most (and similar) significant impact on all manufacturers, given their unique circumstances, apparel manufacturers must, therefore, thoroughly investigate, evaluate their processes and engage in cross-departmental discussions to identify the specific areas of their business that would benefit the most from digitisation. See Figure 1 to know what actions need to be taken to address apparel supply chain issues.

In response to global supply chain challenges, AD Academy (Apparel Solutions Online University by Avery Dennison) is co-hosting a virtual event with Apparel Resources on 14th December 2023 (Tuesday) on the theme ‘Bringing Speed, Flexibility and Visibility to the Apparel and Footwear Supply Chain’ for the South Asian industry.

This one-hour webinar will bring together key opinion leaders, manufacturing technology experts and supply chain professionals from across the South Asia region. It offers a platform for business leaders and experts to connect, engage and learn strategies to navigate shorter fashion cycles and increased variations.

The webinar will explore the pressing issues affecting the industry and reveal how digitisation can transform apparel and footwear manufacturing processes and supply chain. The audience in this webinar will be able to:

- Know the trends that have impacted and headwinds that will impact the apparel industry going forward

- Translate these headwinds (rising cost, unpredictable demand, now or never, shortage of skilled labour, etc.) into capabilities that factories need to build to weather the same

- Understand the foundational elements of Industry 4.0 and how these link to building capability to face the headwinds

- Learn how these can be applied when apparel businesses look at end-to-end apparel value chain and benefits

- Know some examples/impacts of application on digitisation that have helped improve responsiveness, productivity and agility in proven businesses

- Get actionable tips for improving warehouse, transportation and logistics

The speakers in this webinar are renowned subject matter experts including:

- Kenny Liu, VP & GM, South Asia and EMEA, Apparel Solutions, Avery Dennison

- Yusuf Saleem, CEO Process Excellence, MAS Innovation (MAS Holdings)

- Dominic Tse, Senior Manager, Customer Success Operations, In-Plant Printing Solutions, Apparel Solutions, Avery Dennison

Participation in the webinar is complimentary and you can register at ‘NO COST’ through the following link –