In today’s global crisis where there is an existential threat to the world, we need action where everyone in their own small way will have to be an agent of positive change that is real and tangible.

“We chose ‘Planet’ to be the first word in our business vocabulary when we were thinking about setting up Echotex as a business proposal, back in 2006. Not many businesses placed Planet as the central pillar at that time. Later, we selected the four Ps as our company mantra,” adds Quais Shafiq Hassan, Managing Director of Echotex Limited (a vertical set-up with knitting, dyeing, digital and screen printing, laundry and garmenting facilities).

The four Ps that stand at the heart of Echotex’s core principle are Planet, People, Product and Partner even as the state-of-the-art manufacturing facility continues to focus on efficiency, productivity and worker welfare, pioneering ethical practices to help safeguard and improve the well-being of its growing workforce while also ensuring sustainable production processes to come up with best quality offerings that do not compromise with the environment or its ethical values.

Genesis etched in transparency

The company started garment manufacturing in 2008 and textile production in 2009 even as it won the National Environment Award in 2010 for its effluent treatment while bagging its first orders from New Look, Debenhams, Peacocks and Primark.

Having started with only six lines of sewing, cutting and finishing, the company in a span of just ten years increased its production lines to 120 with an average production of over 7.5 million pieces (per month) of knitted jersey for women, men and children and denim for women, men and children catering to names such as Asos, H&M, Inditex – Zara and Bershka, Mango, Morrisons, New Look, Ninety Percent, Primark, Sainsbury’s, Varner even as it continues to do extensive licensed printed products including for Disney, Marvel, Universal, Warner Brothers and many more.

| Starting with only 6 lines of sewing, cutting and finishing, the company in a span of just ten years increased its production lines to 120 with an average production of over 7.5 million pieces (per month) of knitted jersey for women, men and children and denim for women, men and children. |

Simultaneously it started manufacturing fabrics in recycled/organic/BCI cotton, recycled and virgin polyester and nylon, stretch fabrics with elastane/recycled elastane with various blended compositions (all are in knitted jersey construction, including single and double jersey, ribs, sweats, pique, ponti, waffle, pointelle, feeder and engineered stripes).

Environmental endeavours: the driving force

Looking after the environmental benefits for people and products which ultimately ensures business sustainability, Echotex continues to take sustainable strides to ensure its production practices protect the planet for future generations.

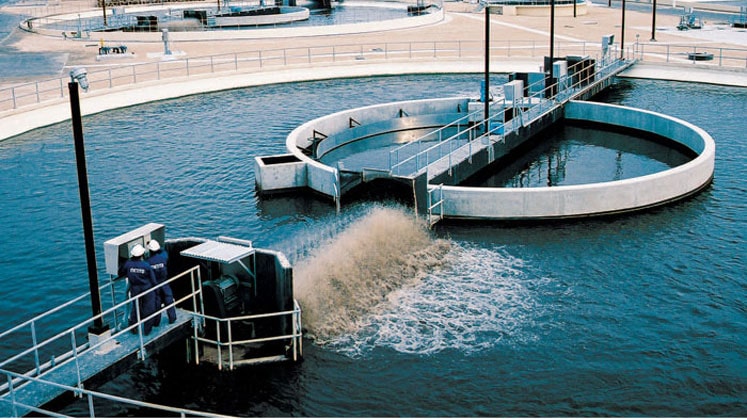

One of the biggest LEED Platinum certified facilities in the country, the company is also the first-of-its-kind in Bangladesh to establish a modern effluent treatment plant (ETP), treating 100 per cent of wastewater to a standard far above the minimal requirements, which earned it Bangladesh Government’s highest recognition – National Environmental Award in 2010, just six months into operation.

The ETP of this LEED-certified manufacturing facility has the capacity to treat 4250 cubic metres of water per day even as it operates as a bio-chemical plant comprising of an Equalisation Tank, Ozone Tank, SBR (biological), IT Tank, IPS, Activated Carbon and Multi-Graded Sand Filter.

What’s more, to avoid bias, a reputable third-party laboratory visits its facility, collects samples of water and ETP sludge and analyses them according to ZDHC wastewater guidelines, before reporting the results to the brands concerned.

It is the first contributor to the Road Map to Zero from Bangladesh in its sector. Echotex is one of the very few Bangladesh companies in the textile industry that is a BLUESIGN-approved partner. This means that it has the highest measure in the safest path in environmental chemistry.

Water and energy conservation

Unlike the other dyeing plants in Bangladesh, Echotex’s fabric dyeing plant is more than four times efficient as it continues to embrace the latest technology to dye per tonne of fabric, using only 45,000-50,000 litres of water.

Meanwhile, in terms of rainwater harvesting, it has started to harvest rainwater on the roof of its garments, dyeing and finishing, maintenance and utility buildings (1,25,000 sq.ft.) so as to use it directly in wet processing, the aim of which is to reduce dependency on groundwater reserves while to save energy, the green manufacturing unit has installed highly-efficient LED lights in all its sewing machines as well as garment finishing floors, thereby reducing electricity consumption significantly while also lowering the factory’s carbon emissions.

Today, all its sewing machines are controlled by a servo drive that protects motor life and conserves electricity use by 60 per cent.

Simultaneously in washing, finishing, dyeing and garments ironing section, Echotex has installed condensation traps and condensate recovery pumps (the condensation is collected and transferred to the boiler feed tank, reducing the amount of energy needed to heat the rest of the tank).

It cogenerates air conditioning of its entire office building, completely from its waste hot water. It has just commissioned its first 1.2 MW solar plant on its rooftop, hoping to double this over the following year.

Green sourcing leading the way

The trendsetter as it is in more ways than one, the company puts major emphasis on green sourcing of raw materials in its supply chain and considers both environmental and social criteria when it comes to selecting external and internal suppliers.

From the life cycle assessment of each product to the thoughts of the working population and initiatives for compliance, Echotex is proficient in every arena even if the supply chain continues to be persistently checked for any changes that can be made to supply superior items to the clients.

“Our merchandisers, with the help of the sourcing office, social and environmental compliance teams guarantee that all the items we purchase meet the buyer’s criteria from all angles, i.e., specialised, social and natural compliance. In addition, most of our providers are chosen or designated by our buyers through rigorous assessment of their compliance,” underlines Zahed M bin Quasem, Echotex’s Executive Director, even as he adds in the textile industry, dyes and auxiliary chemicals are the major sources of water pollution while some of the compounds utilised within the material are chemicals which are persistent neurotoxins and endocrine disruptors.

To diminish those impacts, the ZDHC Foundation published a list of prohibited chemicals and their limits in textile wastewater, which Echotex, as an environmentally responsible organisation follows to the T.

It utilises most of the colours and chemicals which comply with ZDHC’s getaway Level -3 certification – the most elevated level of environmental security certificate for textile chemicals.

“We source our dyes responsibly. Being a BLUESIGN-approved partner, it compels us to select and use dyes and chemicals that are secure for both the environment, as well as, human well-being,” claims Hassan.

Employee welfare: the driving force

“We feel the finest services from our employees can be received if they feel comfortable in their jobs and have their rights and entitlements met. As a result, we have no temporary or outsourced staff. All of our employees have permanent contracts. We give every worker a printed pamphlet with information on their rights, benefits they may get and the current codes of conduct,” explicates Quasem.

Echotex invests in a variety of social programmes for its workers and employees. There is a daycare centre, workers’ grocery facility sold at cost price, saving them at least 15 per cent in cost, along with free breakfast, lunch and dinner, depending on the shift one is working in.

The HR department of the company is in charge of employee well-being, which is overseen by the Director, HR and Ethical Trade.

“Our ultimate aim is to provide a proper balanced diet for all employees even if each day, we cook hot lunch on-site for all (16,000 employees), free of cost. These meals not only improve their health, but also ensure high productivity in return,” Shafiq claims.

| Echotex invests in a variety of social programmes for its workers and employees. There is a daycare centre, workers’ grocery facility sold at cost price, saving them at least 15% in cost, along with free breakfast, lunch and dinner, depending on the shift one is working in. The HR department of the company is in charge of employee well-being, which is overseen by the Director, HR and Ethical Trade. |

About 100 per cent of Echotex employees enjoy the benefits of health insurance, since 2017, under which every employee gets medical benefits for illnesses, injuries, or for other reasons as per the company’s guidelines. Health insurance has been extended to both parents and two children of each worker since 2022, possibly the first-of-its-kind in this industry.

Thanks to its efforts towards sustainability and worker welfare, Echotex has been successful in registering overall growth even if in today’s challenging global market scenario, it continues to plough a significant part of the profit earned back into employee engagement, welfare and sustainability endeavours, to keep the growth curve going.