The days of handcrafted attire are passé and now technology is the buzzword in all segments of the industry. Industrial sewing machines have reinvented and completely revolutionised the way clothing is produced. In this competitive phase of change and up gradation, FDM, has emerged as a player who has re-invented the way industrial sewing is conducted to the advantage of global manufacturers.

The multinational was established three decades ago in China as a motor manufacturing unit supplying to machine manufacturers, now it has its own brand of machines-FDM. The company deals in everything from computerised lock stitch sewing machines, hi-speed over lock machines, computerised auto thread trimming machines, etc. With its head office in China, the company sports branch offices all over the globe including an office in Bangalore, India too.

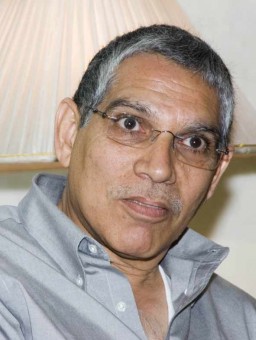

Opening doors 4 years ago, FDM India has within such a short span, grown to become a respected name in the Industrial sewing space. Today, the machines from the company are the one-stop solution for matchless quality products. They are extremely hi-tech, effective, efficient and cost –sensitive. “Quality is our top priority, our machines churn out quality products and we offer value for money to all our clients,” says the country manager FDM, Yogesh B.

The superior quality of the products sown on the machines from FDM, speaks for itself and the company delivers better than the best in the business, no wonder leading exporters are extensively using machines from the company with over 9000 sewing machines sold in India in the past 4 years. This corroborates the fact that clients all over rely on FDM when it comes to sewing their top brands. Gokaldas Exports, Bombay Rayon Fashions, The Shirt Company, Scott Garments are some of the premier buyers.

Dinesh Hinduja, Director, Gokaldas Exports, has full confidence in FDM and its products. He strongly endorses the same. “We have purchased over 5000 single needle machines from FDM, China in the last 3 years and find the machines perfectly in order for high class sewing of garments and the service rendered by FDM is meticulous and flawless,” he says.

FDM sewing machines add to the efforts of the industry to cut cost as they consume less power than other machines. However, the management is not content with success already achieved and they constantly innovate on existing models, along with coming out with new and improved models. “Plans are also underway to expanding into the northern markets of Delhi, Jaipur, Ludhiana, along with Bombay in the west are also shaping up quick and well,” informs Yogesh.

Maggi, Imp & Exp Section Manager of FDM says, R&D is an integral part of the product development and innovation process at FDM and this puts them ahead of others in the market.

Selling through a nominated distribution network, since they feel that the distributors are better placed in terms of market intellegence, the company is working with Mahaveer Industrial Suppliers Pvt Ltd., for the Indian market.

Together the team takes extra care of after sales services and training. Technicians from the Bangalore office are available at all times for any services within India and in case of larger issues, assistance to clients is made available even from China.

Yogesh considers India as one of the booming markets and confirms that many more expansion ventures are in the pipeline for the company.

With India as a growth region, FDM machines shall present itself shortly with new range of machines at the Bangalore International Exhibition Centre during Garment Technology Expo, between13 – 15 July 2007.