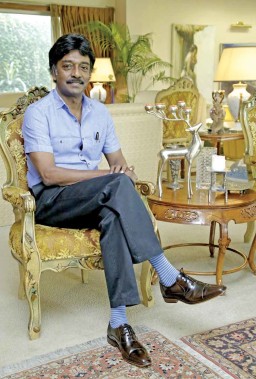

“My approach to business has evolved,” says Sayeeful Islam, Managing Director, Concorde Group, in an exclusive interaction with Apparel Online. Prioritizing quality as his aim in life, he shares that he has developed on this fundamental and as the company grew, he also realized the value of efficiency, loyalty to the company, workers and customers and sustainability both within the company and in respect to the environment. No wonder, today the growth path for the company is ‘sustainability’ both within and outside the company.

After completing his studies in the US and returning to Bangladesh, nurturing the dream to build his country, Sayeeful Islam started the company from the ground and grew up with the help of German and Korean technicians. When the company started, it was a part of the 12 founding members of the BGMEA, out of which now only 6 remain. “When I started the business, I had nothing – no money, no experience, no management skills, and no management pool. But I had the will to succeed and since then I am constantly upgrading with advanced technologies and with the help of trained personnel,” says Sayeeful. From a humble origin as the agents of the renowned business group DHA, Concorde Garments Group, one of the oldest business houses in Bangladesh, has now strengthened its grounds in the manufacturing and export of garments, textiles and IT.

Claiming to be one of the leading manufacturers of ‘full-make shirts’ (a shirt in which all the seams are sealed with tape) in Bangladesh, Concorde Garments has two garment manufacturing plants – Concorde, that has an expertise in handling full make shirts in Mirpur; and Tulip Garments for blouse production, located in Ashulia. The company employs around 4,000 highly skilled and motivated workers.

Though, the group started off with Cut-Make-Trim business model as the customers were providing the fabric, but now it actively participates in the sourcing of the fabrics and accessories. Among the market leaders in Bangladesh for shirts, Concorde aims to lead in blouse manufacturing also. “We do not have any plans for expanding further until we have stabilized Tulip,” says Sayeeful, emphasizing the dimensions of stabilization as efficiency and being the finest in their space. The company is steadily increasing its manpower as it has 12 installed lines in its plant at Tulip Garments, out of which only 5 are operational.

In the meanwhile, Concorde has seen an exponential growth in its interlining business and from 400 customers today, there are major expansion plans to increase capacity to reach many more customers.