The devil is in the details and nowhere is that more true than in fabric quality control. While many manufacturers are still logging defects manually, only a few have started using AI to grade fabric quality at scale. Traditionally, fabric inspection has relied heavily on manual labour, with a speed of just 10 yards per minute and only about 70% defect detection accuracy. AI, on the other hand, doesn’t just find tiny flaws, it also understands how much they matter. It grades each fabric roll in real time as A, B or C, right on the production floor. This kind of smart grading helps teams plan cutting better, allocate fabric more efficiently and avoid unnecessary waste. It also speeds things up across departments. In fact, there are now systems available in the market that are fully automated, capable of running 24/7 and inspecting fabric at 120 yards per minute, while achieving up to 99% detection accuracy. They also support real-time sync with ERP. As soon as defects are found, the system automatically shares reports with ERP to reroute fabric or notify suppliers without delay. This helps eliminate production hold-ups and keeps workflows moving smoothly. AI can also be easily incorporated to existing fabric inspection set-ups, whether you are working with grey, finished or dyed fabrics. It supports all major fabric types, including knits, woven and technical textiles, using defect libraries trained specifically for each material. With direct plug-ins for major ERP and PLM systems, connecting to your preferred software is quick and hassle-free.

Challenges of the 4-Point System

The commonly used fabric inspection systems include the 4-Point system.

For years, factories have relied on systems like the 4-point inspection to spot defects in fabric. It assigns points to flaws depending on their size, up to a maximum of 4 points per defect. The total number of points per 100 square yards (called PPHSY) is used to judge the quality of a fabric roll. The lower the PPHSY, the better the fabric.

But here’s where things get tricky. Each buyer sets their own ‘acceptable’ point limits. Buyer A might allow 20 PPHSY per roll, while Buyer B is stricter and allows only 18. Some even give two limits – one for each roll and one averaged across a full lot. So, you could technically pass the 4-point test, but still end up with hidden production headaches later. The 4-point system doesn’t tell you how many defective panels you’ll get after cutting or if the defects will fall in visible areas. This is where AI can step in and make a huge difference. AI-powered inspection tools don’t just assign points. They scan fabric in real time, detect even the tiniest issues and also map where the defects are. That means you don’t just know how many points a fabric roll has, you know exactly where the problems are and how serious they are. Here’s how AI addresses some of the pain points of the 4-point system:

Predictive defect mapping: Instead of counting only the size of a flaw, AI can tell you whether that defect is likely to affect multiple panels during cutting, giving you visibility into how many usable panels you’ll actually get from a roll.

Automated panel planning: With defect data fed into your CAD or cutting software, you can automatically plan your marker in a way that avoids known defects, reducing panel rejections and rework.

Standardisation across buyers: Since AI systems can be trained on every buyer’s quality rules, it’s easy to grade rolls differently depending on what the buyer allows, instead of manually interpreting point limits for each client.

Real-time sync with ERP: AI can flag risky rolls instantly and notify procurement or production teams. If a roll is going to create more trouble than it’s worth, you’ll know before it hits the cutting floor. In future, systems will learn and suggest the best ways to use defected parts of fabric such as for pockets, linings or other smaller components. By using digital twin models, factories can even trace every step of production, ensuring quality and efficiency from inspection to finished product.

Costs, Returns and How to Choose the Best Option

AI-powered fabric cutters can make a big difference for factories that handle large orders or need very accurate cutting such as in sportswear, lingerie or jackets. Basic AI cutters, which cost around US $ 10,000 to US $ 30,000, are suitable for small factories with simple cutting needs. These machines automate the process but come with limited speed and fewer features. Mid-range cutters, priced between US $ 30,000 and US $ 70,000, offer better speed and accuracy, making them a great fit for medium-sized factories aiming to scale up their efficiency. On the higher end, cutters costing US $ 80,000 to US $ 150,000 or more deliver high performance, support ERP and CAD integration and are ideal for large factories handling complex orders.

But is it worth the money? Let’s talk ROI!

The basic formula is: ROI (%) = (Profit or savings from the technology – Total cost of investment) / Total cost of investment × 100

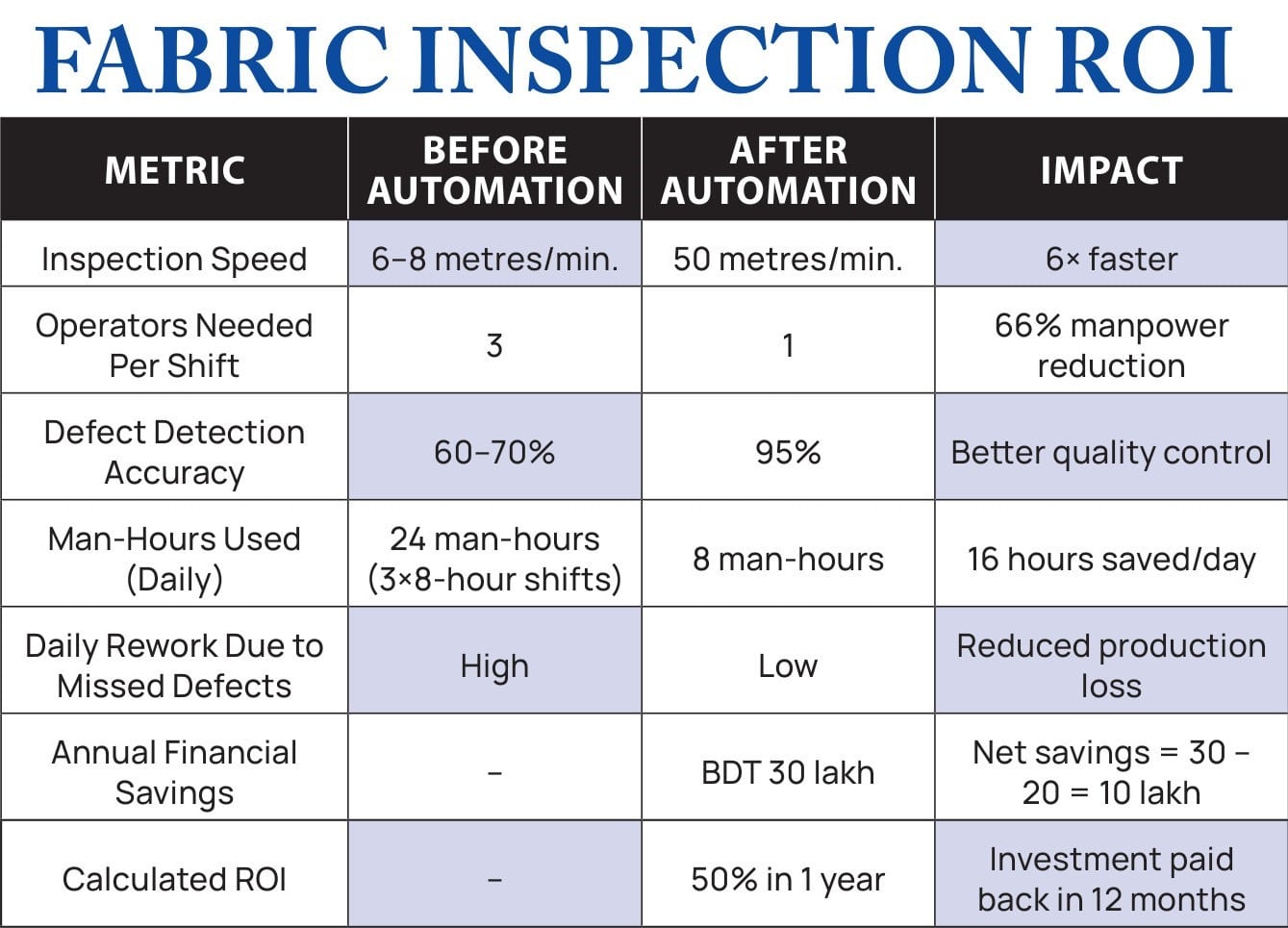

Let’s take a real example from Bangladesh. A woven garment factory decided to shift from manual fabric inspection to an AI-powered system, investing BDT 20 lakh in total, which covered installation, hardware, software and training. Before the upgrade, the factory struggled with slow inspection speed of just 6 to 8 metres per minute, needed three operators per machine and still ended up missing many defects. This led to frequent reworks, shipment delays and complaints from buyers.

After adopting the automated system, the improvements were clear. Inspection became much faster, fewer operators were needed, defects were identified in real time and overall quality improved. As a result, the factory saved time, reduced fabric waste and delivered better products—leading to fewer complaints and stronger relationships with its buyers.

Therefore, fabric inspection may seem like a back-end process, but it has a front-line impact on product quality, lead time and customer satisfaction. For Bangladesh to shift from making large quantities to higher-value products, factories must use AI for quality control. By using digital inspection tools, they can attract buyers who pay more for reliable, compliant and consistent products.

Fouzul Imran Khan, MD of Benchmark Apparels Ltd., since its inception in 2010, is contributing significant value to export basket of Bangladesh through RMG. Since 2023, he has been an active member of board of directors of BKMEA, engaging and representing himself in various internal as well as external affairs as a member of the board.